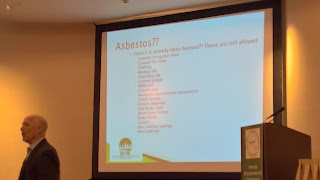

Happy New Year! May your New Year be healthy, profitable, & peaceful! This blog post we will talk about the silica regulation and what the fuss is all about. We've heard from some of our clients that they are concerned that the regulation is like the asbestos regulation. Well in reality the regulation is more like the lead regulation than the asbestos regulation. The big drop in the

permissible exposure limit makes it similar to the asbestos regulation in that visible dust exposures may result in violations, but that's where it ends for similarity. Table 1 of the silica standard is similar to the 1926.62 (d) (2) of the lead standard which is Protection of Employees During Assessment of Exposure. Where based on a certain task (i.e., scrapping

lead paint) the employer must comply with all parts of the standard, including the use of

respirators. Table 1 in a sense has a similar requirements.

|

| Spraying Water to Keep Dust Levels Down Will Become Common Place |

The

Occupational Safety and Health Administration (OSHA) released the final rule for respirable

crystalline silica 1926.1153 on March 25, 2016 with compliance dates more than one year past the publication date. Giving the various industries regulated by the standard plenty of time to comply. In fact, the

construction industry was the first industry required to comply by June 23, 2017, however, the current administration delayed the standard until September 23, 2017 giving the construction industry additional time to comply. In addition,

OSHA's silica website is quite robust with guidance documents in helping the industry comply. With all this time to comply, including

challenges to the standard that the courts eliminated, and equipment manufacturers having time to review Table 1 of the standard, complying with the standard is pretty straightforward if you are performing any of 18 tasks in Table 1.

Table 1 tasks involve exposures to respirable

crystalline silica when the following

tools are used on concrete, brick, block,

stone, mortar, and other materials that

contain crystalline silica:

- Stationary masonry saws;

- Handheld power saws;

- Handheld power saws for cutting fiber-cement board;

- Walk-behind saws;

- Drivable saws;

- Rig-mounted core saws or drills;

- Handheld and stand-mounted drills

(including impact and rotary hammer drills);

- Dowel drilling rigs;

- Vehicle-mounted drilling rigs;

- Jackhammers and handheld powered

chipping tools;

- Handheld grinders for mortar removal (i.e., tuckpointing);

- Handheld grinders for uses other than mortar removal;

- Walk-behind milling machines and

floor grinders;

- Small drivable milling machines;

- Large drivable milling machines;

- Crushing machines; and

- Heavy equipment and utility vehicles

when used to abrade or fracture silica containing

materials (i.e., hoe-ramming

or rock ripping) or used during

demolition activities; and

- Heavy equipment and utility vehicles when used for tasks such as

grading and excavating.

|

| Doing tasks in this manner, we hope will be a thing of the past! |

If your work involves Table 1 tasks then determine how long your workers do those tasks and follow the requirements. If the requirements require a respirator then you may want to reduce the time period a worker does a task so a respirator is not required. This would be considered an administrative control under hierarchy of controls and perfectly acceptable. Once you have determined the tasks, the controls, and time periods, the next step is to write your exposure control plan. The exposure control plan details the tasks, controls, and time periods/respirator requirements and designating a competent person to ensure the exposure control plan is enforced. The final step is to train the workers and the competent person on the exposure control plan so everyone understands and knows what is required under the plan.

|

| Wearing A Respirator, Adds Significant Costs for Silica Projects |

If your exposure control plan requires respirator, then you must meet the requirements of the respirator standard 1910.134, see

our blog post regarding the directive which tells you how this standard would be enforced. This standard would require a medical evaluation of workers to ensure they can wear a respirator, annual respirator fit testing, and annual training on the use of the respirator. Respirator standard would also require a written program and the designation of a competent person to administer the written program. In addition, the silica standard would require you provide a

medical exam, specifically for silica, if workers use respirators for 30 days or more in a calendar year. This medical would be required every 3 years. The medical must include:

- medical & work history;

- chest x-ray;

- pulmonary function test;

- physical exam focused on the respiratory system; and

- testing for latent tuberculosis infection.

After all of the above, the final steps in compliance is maintaining the records, in accordance with 1910.1020, and updating the plans on an annual basis. 1910.1020 standard requires that exposure records be maintained for 30 years from the date of creation and medical records be maintained for duration of employment plus 30 years.

|

| More Projects Will Look Something Like This |

Based on the above information, we think it is pretty obvious that you want to eliminate tasks that involve the use of respirators or reduce the amount time a worker does a task that might require a respirator. Doing so eliminates the need for the silica medical exam and all the requirements under the respirator standard. The long term costs involved with meeting the requirements for using a respirator (silica medical exam & respirator standard requirements), we think would outweigh the cost of improving equipment used by workers to meet the requirements of Table 1 for each of the tasks. We have added some silica courses to our schedule to help you comply with the new standard. Visit our website for more information. Happy New Year and Be Safe!