When we first became an asbestos consultant over 39 years ago, we remember people telling us that buildings will remove all their

asbestos materials in 5 years, 10 years, or 15 years depending on who we talked to. Well, asbestos is still in

buildings and this article is about why there are many years still left in this industry. In the construction industry, there are some who think that a certain

year was the end of asbestos use in building materials. Over the years we have reviewed many asbestos

inspection reports or property transfer reports (phase I environmental audits)

reporting that since a building or a part of a building was built after 1980

there are no asbestos-containing materials.

The companies making this statement assume that the federal government

banned all asbestos-containing materials in 1980. In

|

| Terrazo? |

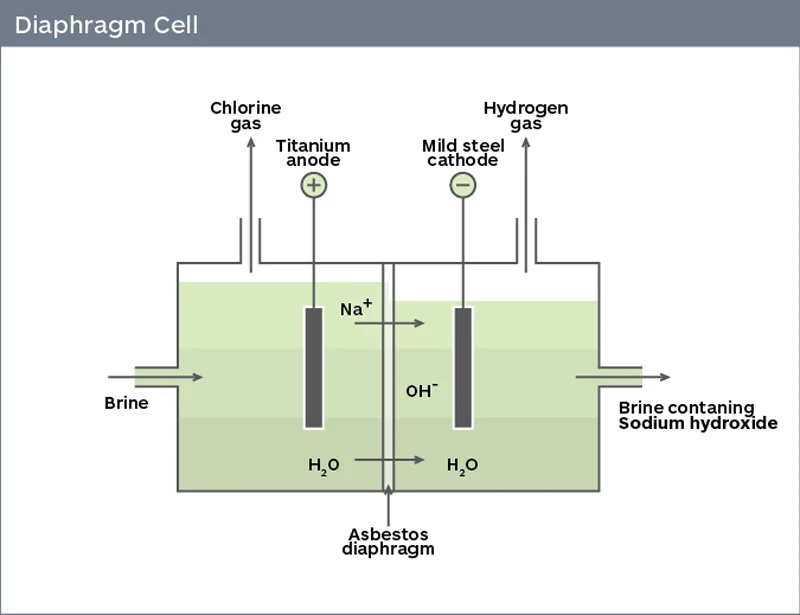

The federal agency with

the responsibility for banning asbestos is the EPA. This agency, under the National

Emissions Standards for Hazardous Air Pollutants (NESHAPS), banned the use of

asbestos for sprayed-on application of fireproofing and insulating in 1973 and

for decorating purposes in 1978. In 1975 EPA’s NESHAPS regulation

also banned the installation of pre-formed (molded) asbestos block insulation

on boilers and hot water tanks and the wet-applied and pre-formed (molded)

asbestos pipe insulation. Since two of

these bans did not go into effect until after 1974, the

|

| Electrical wire insulation |

Is there an appropriate

end date for asbestos use in buildings? Some headlines indicate the answer to this question is no. These headlines indicate that some current building

materials are contaminated with asbestos or still contain asbestos sufficiently

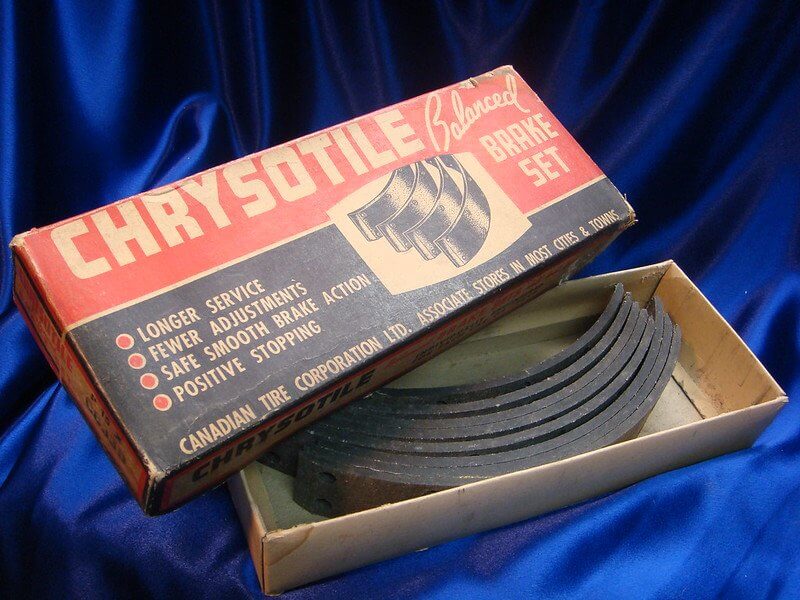

enough for the materials to be considered asbestos-containing materials. For example, the Asbestos Disease Awareness

Organization (ADAO) reported in November 2007 that they sampled a number of current

building materials and determined that DAP’s “33” window glazing and “crack

shot” spackling paste and Gardner’s leak stopper roof patch all contained

asbestos. DAP’s “33” window glazing was

purchased at Home Depot and Lowes for the purpose of the study and contained 2.6%

tremolite, and 0.13% chrysotile asbestos (2.73% total asbestos). DAP’s “crack shot” spackling paste was also purchased

at Home Depot and Lowes and contained 0.98% tremolite, and 0.066% chrysotile

asbestos (1.05% total asbestos).

|

| asbestos woven products |

The Liability of Ignorance

Since there is no total ban on the use of asbestos

in building materials, it means that 1974 or 1980 are not appropriate cut off

dates on the use of asbestos in building materials. This means all buildings or facilities no matter when they were constructed should be inspected for asbestos-containing materials. EPA's NESHAP regulation 40 CFR 61.145 Standard for demolition and renovation requires buildings/facilities to be thoroughly inspected before the renovation or demolition, no matter what date the building was built. It also means that the construction industry

should be very careful when working on buildings after these dates because it

is possible that if an asbestos inspection or survey was done it may have not been done properly. From our experience, we've seen inspectors not sample roofing materials, joint compound, sheetrock, textured paint, siding shingles, and window caulking just to name a few building materials that should be sampled. Building owners,

banks, facility managers, architects, engineers, general contractors, and

subcontractors should not think that because the EPA regulation requires an inspection, and if the inspection is not done correctly that there is no chance for a violation or liability. OSHA requires that employers inform their

workers of all the potential hazards at a project (job) site. Should materials that were not inspected turn

out to be asbestos-containing or even if the sample result is 1% or trace asbestos and the exposure exceeds the permissible exposure

limit (0.1 fibers per cubic centimeter based on an eight hour time-weighted

average) or the excursion limit (1.0 fibers per cubic centimeter over thirty

minutes) the employer would be in violation of the OSHA asbestos

regulation. No matter the construction

date of the building. The building owner

could then face third-party litigation from the workers if they develop a

disease (mesothelioma being the most significant because of its direct tie to

asbestos exposure) from such an exposure. In addition, the AHERA regulation which

applies to public and private schools (kindergarten to 12th grade) requires that architects that design new

schools or renovations of existing schools certify that the building materials

used do not contain asbestos. Utilizing safety data sheets (SDS), which are required for most building

products, to certify the products would not be sufficient considering that

DAP’s SDS (discussed above) did not mention the asbestos contamination in the product and the NESHAPS regulation requires building materials to be sampled for the content of asbestos. Meaning the only way to certify the products

to limit liability would be to have suspected materials sampled and analyzed

for asbestos. It is very important for

building owners, banks, facility managers, architects, engineers, general

contractors, sub-contractors, asbestos inspectors, and phase I environmental

auditors to realize that although the asbestos regulations refer to dates before 1980, inspections are advisable and required under the EPA's NESHAPS & OSHA's asbestos regulations since the

installation of asbestos-containing materials into buildings can continue to this

day.

|

| Fire Door |