- Response Actions; §763.90 (i)

- Appendix A (to Subpart E) - Interim Transmission Electron Microscopy Analytical Methods - Mandatory and NonMandatory - and Mandatory Section to Determine Completion of Response Actions

AHERA allows final clearance air sampling to be done by phase contrast microscopy (PCM) methodology for projects less than or equal to 160 square feet (SF) or 260 linear feet (LF) by the National Institute for Occupational Safety and Health (NIOSH) 7400 methodology (Issue 3: 14 June 2019 is the current issue). For projects greater than 160 SF or 260 LF clearance shall be done by the AHERA transmission electron microscopy (TEM) method (requirements at 763.90 (i) (4) and Appendix A). Since this article's purpose is to discuss why we should not be using the PCM method we will focus our discussion on this method specifically. An important point to remember is that the method was designed for personal sampling of workers in environments with actual asbestos exposures. AHERA adapted the method for clearance requiring that each sample must be less than or equal to a limit of quantitation (LOQ) for PCM of 0.01 fibers per cubic centimeter (f/cc).

Over the years, it has become abundantly clear that the PCM method should not be used for clearance sampling. The top five reasons it should not be used for clearance sampling are:

Size of the Fibers Analyzed

The rules for the NIOSH 7400 method specifically require the microscopist to count only fibers that are greater than 5 micrometers (microns) length. When it comes to diameter it is questionable whether fibers less than 0.25 microns in diameter can or cannot be detected by the method. All other fiber lengths and narrow widths are not counted they are too thin with normal PCM resolution. At the Professional Abatement Contractors of New York 2023 Environmental Conference, Lee Poye, Vice President Emeritus, Eurofins Built Environment, discussed his presentation "Asbestos in Human Tissue and the Environment - Does Size Matter?"

|

| Lee Poye Presenting at PACNY 2023 |

| ||

|

- What's the skinniest PCM fiber a "typical AMT" can see? 0.18 micron.

- Just how much chrysotile is missed by PCM? Almost ALL of it!

- What % of chrysotile fibers detected in human tissue would've been visible by PCM? Maybe 2% to 3% at best!

Is the Work Area Actually Clean?

In 2003, Applied Occupational and Environmental Hygiene published a study called "Asbestos Release During Removal of Resilient Floor Covering Materials by Recommended Work Practices of the Resilient Floor Covering Institute" by Marion Glenn Williams, Jr. and Robert N. Crossman, Jr. from the University of Texas Health Center at Tyler, Tyler Texas. The major points from this study were:

- Asbestos used in flooring materials is Grade 7 - Shorts and Floats. The dimensions of this material are very small and may not be resolvable by the Polarized Light Microscope (PLM). This is why New York State Environmental Laboratory Approval Program (NYS ELAP) requires floor tiles to be analyzed as a nonfriable organically bound (NOB) material (analysis by PLM and if negative result for asbestos, then analysis by TEM).

- Many research studies have found the preponderance of fibers at autopsy left in lung tissue, pleural plaques, and lymph nodes of persons who have occupational asbestos exposure are shorter than 5 microns in length.

- The NIOSH 7402 TEM method is flawed because it underreports the amount of asbestos in the samples because it ignores all fibers less than or equal to 5 microns and all those fibers longer than 5 microns but less than 0.25 micron in diameter.

- AHERA TEM method counts for total asbestos structures per cubic centimeter averaged 22 times greater than the PCM fiber counts on the same filters.

- AHERA TEM asbestos concentrations obtained during mastic removal with a commercial mastic remover averaged 11 times higher than those measured when removal used amended water.

- The study also found that there was considerable amounts of asbestos dust settled on exposed surfaces during tile removal. Indicating a need to thoroughly HEPA vacuum and wet clean surfaces or dust may remain that could be re-entrained by occupant activity.

- The study also indicates that workers in these areas, would not have to wear respirators, so anyone in these areas would have inhaled asbestos fibers or structures of respirable dimensions.

At the 2017 PACNY Environmental Conference a debate occurred about our call for TEM clearance sampling for all asbestos floor tile projects based on the above study. This debate led to our writing the article Asbestos Floor Tile Debate Results Post and our article in Healthy Buildings. Our major points were:

- When using the AHERA TEM method for clearance, what was the typical size of the fibers found? The answers we got were 58.8% less than 5 microns; 29.4% of both sizes were equal amounts; and 11.8% greater than 5 microns.

- Have you ever encountered during asbestos flooring removal when utilizing both the NIOSH 7400 (PCM) & the AHERA (TEM) methods of analyses, that the NIOSH 7400 passed while the AHERA TEM method failed? The answers we got were 52.6% yes, 36.8% no, and 10.5% never used both.

- AHERA TEM method counts for total asbestos structures per cubic centimeter averaged 22 times greater than the PCM fiber counts on the same filters.

- AHERA TEM asbestos concentrations obtained during mastic removal with a commercial mastic remover averaged 11 times higher than those measured when removal used amended water.

Mr. Snider's presentation found workers performing floor tile projects had significant Take-Home Asbestos Exposure. These points all bring up the question of whether the work area is actually clean when we use the PCM method. Many building abatement projects are passing by PCM that would not pass clearance by TEM.

Is 0.01 fibers/cubic centimeter (f/cc) Safe?

- Among the 1023 industries recorded for those having mesothelioma, the most frequent cases were found for those in manufacturing (n = 225, 22.0%), construction (138, 13.5%), and education services (66, 6.5%)….

- Males (583) or persons aged >40 years (658) at the time of diagnosis tended to have worked in industries traditionally associated with mesothelioma (e.g., construction), while females (163) or persons aged 20–40 years (27) tended to have worked in industries not traditionally associated with mesothelioma (e.g., health care).

- Current occupational exposure occurs predominantly during maintenance and remediation of asbestos-containing buildings.

- Continuing occurrence of malignant mesothelioma deaths in persons aged <55 years suggests ongoing inhalation exposure to asbestos fibers and possibly other causative EMPs.

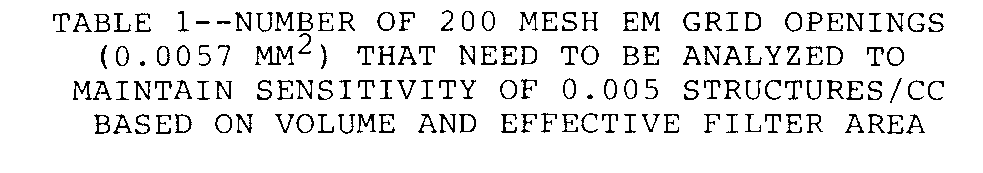

The above table is from the above referenced material. However, we have added the last column based on a 30-year latency period which gives an interesting perspective based on when the person most likely was exposed to asbestos. Consider that over 650 individuals were most likely exposed before working age. this could result from exposures due to take-home exposure, do-it-yourself projects, or from attending schools that are not managing asbestos properly. It is also interesting to note that the number of mesothelioma deaths between 1999-2015 has remained roughly the same, between 2479-2873 individuals.

- Many believe or have been misled to believe that PCM sampling is the same as TEM sampling in terms of sampling volume. This is not the case. A PCM sample volume meeting AHERA clearance requirements are not at 1200 liters. To do so is outside of the NIOSH 7400 method requirements for this purpose. Even others have used the limit of detection sample volume to collect 560 liters.

- In the NIOSH 7400 method, the issue regarding "relatively clean" environments" is addressed on page 4, number 4, note number 1 which states "In relatively clean atmospheres, where targeted fiber concentrations are much less than 0.1 f/cc, use larger sample volumes (3000 to 10,000 liters) to achieve quantifiable loadings."

- Even though the formula calculates that 3,850 liters of air should be collected, many people use note 1 to collect 3,000 liters of air for clearance. Either way clearance samples should be collected using no less than 3,000 liters of air as the minimum allowed for the NIOSH 7400 method requirements and AHERA compliance.

The NIOSH 7400 method, utilizes the formula above to determine the amount of time needed to achieve the fiber density, E, for optimum filter loading. So, the minimum density the method allows is 100 fibers per square millimeter (mm2). The Ac is the collection area for a 25-mm cassette which is 385 mm2. The Q is the sampling flow rate in LPM, and t is the time we are collecting the sample. Modifying the formula to calculate for L or the LOQ concentration, we get this for 560 liters.

- EPA AHERA clearance requirement of less than or equal to 0.01 f/cc is not being met.

- NYSDOL Industrial Code Rule 56 (ICR56) clearance requirement of less than 0.01 f/cc is not being met.

- NYCDEP Title 15 clearance requirement of less than 0.01 f/cc is not being met

As you can see from the results none of the individuals that answered the question are actually collecting the correct volume of air required by the NIOSH 7400 methodology. Improper collection of PCM samples is not meeting the clearance requirements.

The Cost of Clearance Sampling

We know what you are going to say TEM samples cost way more than PCM samples. We agree they do, but not compared to when AHERA first came out. When AHERA first came out there were hardly any laboratories that did TEM analysis and those that did the samples cost between $350-500 per sample. The difference between PCM analysis costs and TEM analysis costs has come way down. A recent quote we received from a reputable laboratory for PCM analysis with a 3-hour turnaround was $12.50 per sample while TEM AHERA analysis with a 4-hour turnaround was $150 per sample. The price difference is smaller than it once was. The odd math is that the difference in price between PCM and TEM for many projects is not even a rounding error to the overall budget, where the total construction budget could be in the millions (renovations).

If PCM cannot see the fibers that cause disease or even determine that the area is clean, is it worth the money or the paper it is printed on when it comes to final clearance air sampling?

TEM should be the only method employed for clearance air sampling!