Future Environment Designs Training Center specializes in asbestos, indoor air quality, industrial hygiene, and occupational safety training programs. We offer New York State asbestos and mold certification courses. We design, develop, and maintain the various indoor air quality, asbestos, and safety programs that are Keeping Your Employees Safe.

Search This Blog

Saturday, July 09, 2022

EPA Clarifies Miscellaneous Materials Sampling - RePublished

Wednesday, August 11, 2021

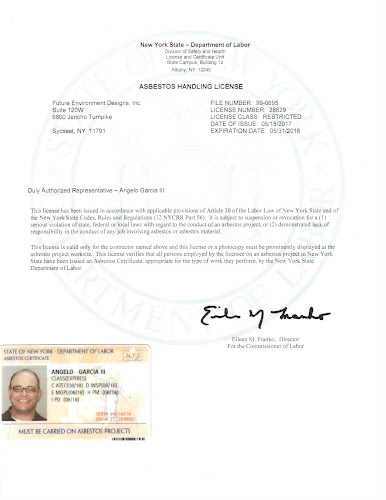

Current Asbestos & Mold Hard Cards Required for Asbestos & Mold Projects! Fast Track Variances on Pause and New Asbestos Attachments for New York City DEP!

New York State Department of Labor (NYSDOL) as of July 31, 2021, is requiring current asbestos and mold hard cards for asbestos and mold projects. Their latest automatic response email claims to be turning around asbestos hard cards in five (5) weeks and licenses in three (3) weeks. That same NYSDOL email says they are turning around mold licenses in three (3) weeks. So it seems the NYSDOL's license and certification unit is back to normal. On the other hand, the New York City Department of Environmental Protection (NYCDEP) is allowing workers whose hard card expired on March 15, 2020, or later to continue to work using their existing card until August 31, 2021. See NYCDEP's Extension of Asbestos Certification Deadline website for more information. In addition, NYCDEP has reinstated the examinations for asbestos as of April 21, 2021.

|

| Asbestos Company License and Worker (hard card) Certificate |

In our blogpost in February 2021, we discussed that NYSDOL's Engineering Services Unit (ESU) came out with 10 Fast Track Variances and that this was a pilot program. On Thursday, July 22, 2021, the Professional Abatement Contractors of New York (PACNY) were notified by NYSDOL's ESU that they were shutting down the Fast Track Variance Program. The following is quoted from the NYSDOL email to PACNY:

"As the results of an increasing number of questions concerning relief granted by some Fast Track Variances (FTVs), ESU has decided to temporarily stop the FTV program. ESU will go back and review each FTV to ensure that the relief granted, and conditions listed in the FTV are consistent with ICR 56 and appliable Federal requirements. ESU will also try to better define when and how each FTV can be utilized. There seems to be some confusion about how some FTV’s are to be used. When ESU completes its review of an FTV, we will reissue that FTV for use moving forward. It is ESU’s hope that this review will not take long. In the meantime, site-specific variances should be applied for as usual via email to me and cc: Edward.Smith@labor.ny.gov"

So it seems if you want an FTV, you will have to apply and wait the time it takes to approve site-specific variances (anywhere from 3-6 weeks).

|

| Asbestos Inspector Initial Class |

Saturday, April 24, 2021

When Do Asbestos Certificates (Hard Cards) Expire Under COVID-19? New Update: No more extensions!

|

| Hard card with picture (certificate) & Company license |

| |

|

Monday, February 01, 2021

NYSDOL and NYCDEP Provide Guidance for Asbestos Project Designers Applying for Variances!

In our blogpost "PACNY's Environmental Conference Day Three - A NYSDOL Surprises with Fast Track Variances!" we discussed the New York State Department of Labor's (NYSDOL) Engineering Services Unit (ESU) announcement at last year's Professional Abatement Contractors of New York's (PACNY's) 2020 Environmental Conference, of a pilot program for certain site-specific variances. These new variances are called Fast Track Variances. These are variances that the ESU has been issuing regularly and don't really change each time an asbestos project designer requests them. ESU has created 10 Fast Track Variances and may create more in the future.

|

| NYSDOL ESU's Ed Smyth discussing variances at PACNY |

In addition, the New York City Department of Environmental Protection (NYCDEP) has released a service notice regarding the filing of an ACP-9 variance request "Variance (ACP-9) Filing Instructions". The service notice gives instructions on the information that must be provided in applying for a variance from NYCDEP. Required documents for NYCDEP include the building authorization letter; the ACP-9 form including fee ($300-$1,800); and the proposed method of work (variance proposal) and layout drawing. NYCDEP also has the equivalent of Fast Track Variances which they call Attachments (there are 13 of them). Visit Future Environment Designs Training Center's (FEDTC's) dropbox folder to access them.

|

| NYCDEP Attachment D & DI are regarding remote decons and decons inside the work area. |

The process for getting a Fast Track Variance from NYSDOL ESU for all intents and purposes is the same for getting a site-specific variance. You will still need a licensed and certified project designer to sign and complete the SH 752 application. The application must be completed fully including the hardship. One difference is no information about the work plan should be included in the SH 752 application. The variance fee is still $350. In section 9, Industrial Code Rule 56 (ICR56) Relief Sought, of the SH 752 application the designer must enter the Fast Track Variance number they are seeking. There are 10 Fast Track Variances:

- Fast Track Variance-1 (FTV-1) is about shutting down the negative air units overnight. The negative air units must run a minimum of 30 minutes after completion of all abatement/cleaning activity for the day and must run 30 minutes after the manometer achieves a negative 0.02 water pressure differential before entering the work area the next day.

- FTV-2 is about exhausting negative air machines to an interior space. The variance requires air monitoring of each negative air exhaust (no banking allowed) and must be exhausted into an existing, vacant room or an area within a larger space isolated, consistent with vacate, restrict entry, & post signs (ICR56-7.4) by barrier tape and warning signs. The location must be adequately sized to accommodate the increase in positive pressure to the area. All openings within 25 feet of the negative air machine exhaust must be sealed with two layers of 6 mil fire retardant poly. The variance includes a process for elevated air monitoring results.

- FTV-3 is about the removal of ACM filled elevator doors intact without impact to the matrix during removal operations. Project monitor required, elevator technician involved with door removal must be allied trades certified, no waiting periods, air samples 10 feet from the barriers, and inside the work area. The most recent final air sample results are the clearance results if they meet the clearance standard.

- FTV-4 is about the removal of ACM filled fire doors intact without impact to the matrix during removal operations. Not surprisingly this variance seems exactly the same as FTV-3 without the elevator technician.

- FTV-5 is about the removal of pipe insulation and dirt in a crawl space. The variance requires attached large project personal and waste decontamination unit but allows, if space limitations, for a small project personal and waste combination decontamination unit in accordance with ICR56-7.5 (c) & 56-7.5(e9). If no public access, it allows 2-layer six-mil fire retardant plastic sheeting in lieu of hardwall barriers. 8 air changes per hour required. Glovebags without tents allowed. Soil removal as per American Society Testing and Materials (ASTM) 1368 (latest edition), Section 9.1.1-9.1.5 inspection criteria. It is interesting to note that the requirement does not include 9.1.6 & 9.1.7 of the standard. 9.1.6 uses a personal sampler on the project monitor during the visual inspection as a representative indication of fiber exposure for re-occupancy and 9.1.7 discusses soil sampling in accordance with ASTM test method D7521. In addition, to the regular air sampling for an asbestos project, air sampling inside the work area is required for the entire work shift based on the size of the project (i.e. 1-minor, 3-small, 5-large). The project requires a prep waiting (4-hours) and a final drying/settling period (8-hour). Clearance is based on the most recent daily abatement air samples collected during cleaning operations.

- FTV-6 is the intact removal of nonfriable ACM components. The variance allows removal inside of tents or removal as part of a larger work area. Removal without tents requires critical barriers and dropcloths. Background sampling and a pre-abatement waiting period are not required. Power tools require manufacturer equipped shroud and HEPA-vacuum. Daily inside work area samples (i.e. 1-minor, 3-small, 5-large) required in addition to the regular during abatement samples. The most recent daily samples will be used to compare to the clearance criteria after the visual inspection by the project monitor. There is only one drying/settling period, time is based on the item being removed can be either 4- or 2-hours.

- FTV-7 is for the removal of non-friable ACM transite piping from below ground. One of the requirements is the regulated area, decontamination units, airlocks, and dumpster area shall be cordoned off at a distance of 25 feet, if not then a daily abatement air sample shall be collected in the reduced barrier. In addition, even if you do the 25 feet condoning off, the variance requires air sampling taken on opposites of the work area at the perimeter barriers. Extending those barriers. In our opinion, this requirement by itself seems onerous. We realize not all projects are in a roadway but for those projects that are this means closing the roadway or closing a few lanes or setting up a sample in the middle of the road which means your shutting that road anyway. Meaning these projects will probably require flaggers to control the traffic around these barriers. The variance allows the equipment operator to be allied trades (see our blogpost regarding the difference between allied trades and operations & maintenance) as long as they only excavate the soil to within 6 inches of the buried pipe and lifting the section out of the trench using nylon slings. Requires a negative pressure tent if sawing or other methods that would render the piping friable. Requires project monitor visual inspection to complete the project.

- FTV-8 is HEPA-drilling to allow for the installations of building system upgrades into ACM joint compound/drywall wall and ceiling. Requires dropcloth decontamination area and dropcloth under each drilling/cutting location. Power tools require a shroud and HEPA vacuum. Requires wet methods (allows shaving cream or foam as a wet method). Supervisor visual inspection as per minor projects.

- FTV-9 is air sampling of elevated exhaust duct locations. Basically, if the negative air exhaust ducts are exhausting at a height above ground where air sampling of the exhaust is not possible, that is this variance. We find this an interesting variance in that most consultants that work on high-rise buildings throughout the state should be applying for this variance.

- FTV-10 is controlled demolition with nonfriables to remain. Requires a full-time project monitor on-site and the individual will have a number of specific requirements. One of the most interesting requirements of the variance is the requirement that the Environmental Protection Agency (EPA) Document 340/1-92-013 "EPA Guide to Normal Demolition Practices Under the Asbestos NESHAP" be consulted by the petitioner to anticipate demolition methods will cause Regulated Asbestos Containing Materials (RACM) to be created. This EPA document published in 1992 is an excellent source of information from EPA about various demolition practices and whether those practices will cause a category I or II nonfriable asbestos-containing material to become a RACM. Air sampling for the variance includes the usual large project requirements for air sampling plus air sampling upwind and downwind of the work area. Soil/Earth/Dirt cleanup has to meet the ASTM 1368, Sections 9.1.1-9.1.5 inspection criteria.

Wednesday, June 17, 2020

PACNY's Environmental Conference Day Three - A NYSDOL Surprises with Fast Track Variances!

|

| Dr.Rutstein speaking about talc litigation |

|

| NYSDOL Panel Discussion |

|

| Future Environment Designs was a Gold Sponsor of PACNY's Environmental Conference |

Thursday, March 28, 2019

Proficiency Day Awards Architects & Engineers 3 Professional Development Hours - PACNY's 23rd Annual Environmental Conference - Day One

|

| Karen Cummings, MPH presenting on the Asbestos Safety Training Program |

|

| Angelo Garcia, III, CIEC, CEOP, presenting on Asbestos Inspections & NYCDEP Changes |

The final presentation was "New York City Title 15 Amendments" also presented by Mr. Angelo Garcia, III, CIEC, CEOP, and again this presentation can be found in the Dropbox folder. This presentation was on the recent changes to the New York City Department of Environmental Protection's (NYC DEP's) Title 15 Asbestos Regulation (formerly known as Local Law 76). These changes were made because of the arrest of 17 NYC asbestos investigators (see the above video on the press conference on the arrests) and the recommendations of the New York City Department of Investigations (NYC DOI). These changes included additional requirements for NYC Asbestos Investigators and some changes to other parts of the asbestos regulations. See our previous blog post on these new requirements.

|

| TS Steakhouse Waitress making the "Gotham" |

Related Articles:

- NYCDEP Asbestos Rule Amendment Goes Into Effect January 6, 2019

- Countdown to PACNY's 23rd Annual Environmental Conference Begins!

Wednesday, March 29, 2017

PACNY's Environmental Conference - Day 1 - And So It Begins!

- EPA accepts electronic record-keeping, but hard copies of the original survey and asbestos management plan must be maintained at the Local Education Agency (LEA) office.

- The LEA must assign and train a designated person to oversee asbestos activities and ensure compliance with AHERA requirements. The designated person must be trained but does not require them to be accredited and does not list a specific course or specific number of hours. It does list specific training topics which include - health effects; detection, identification, & assessment of asbestos; options for controlling asbestos; asbestos management plan topics; and relevant Federal, State, and local regulations for asbestos. As a side note: Future Environment Designs (FEDTC) recommends designated persons take the asbestos inspector (3 day) and management planner (2 day) initial courses to meet the AHERA requirements.

- EPA allows two methods for new additions to existing buildings. An architect or project engineer responsible for the construction of a new school building after October 12, 1988 or an accredited inspector to:

- to sign a statement that no asbestos containing building materials (ACBM) was specified as a building material in any construction document for the building, or

- to the best of his or her knowledge, no ACBM was used in any building material in the building.

- The LEA must submit a copy of this statement to the EPA Regional Office and shall include the statement in the management plan of the school.

- Deficiencies found by the audit included:

- Periodic surveillances were missing or weren't well documented

- Documentation of notifications not included or well documented

- ACBM removal not updated in the management plan

- Clearance air monitoring records not available per AHERA

|

| Mr. Don Pierce of NYSDOL |

|

| Mr. Kevin Hutton of Eastcoast Resources |

- According to the Asbestos School Hazard Abatement Re-authorization Act (ASHARA) an asbestos project designer is required on Public and Commercial Building asbestos projects (including residential buildings with 10 or more dwellings).

- When writing a variance consider your audience: DOL ESU; Abatement Contractor, Project Monitor; Asbestos Control Bureau (ACB) Inspector; Occupational Safety and Health Administration (OSHA) Inspector (Compliance Safety Officer); and the Courts.

- Mr. Smith discussed that his department handles between 1400-1500 variances a year. About 25% are then reopened, with another 5% reopened a second time and another 5% reopened a third time. Mr. Smith also provided us with a list of Pet Peeves regarding variance applications which included:

- Failing to explicitly list what code sections you are requesting relief from

- Don't be lazy and simply submit someone else's variance and state you want to do what is in that variance. Own your work, your client is paying you to apply for a variance on their behalf.

- "State-Wide" emergencies

- Try to limit your write-up to the hardship and proposed steps to be taken to work around the hardship.

|

| Mr. Ed Smith of NYSDOL Engineering Services Unit |

|

| John of TS Steakhouse at Turning Stone Casino |

Related articles

Is It Really Here Again! The 21st Annual PACNY Environmental Conference Starts March 1, 2017.(futureenv.blogspot.com)

Is It Really Here Again! The 21st Annual PACNY Environmental Conference Starts March 1, 2017.(futureenv.blogspot.com)

NYSDOL Roundtable Highlight of PACNY Environmental Conference(futureenv.blogspot.com)

NYSDOL Roundtable Highlight of PACNY Environmental Conference(futureenv.blogspot.com)

Monday, July 18, 2011

Did You Know?

Related articles

- Summer & Fall 2011 Future Focus Now Available Online (futureenv.blogspot.com)

- New York Increases Monitoring of Asbestos Inspectors (nytimes.com)

- NYC DEP Plans Increase In Enforcement On Asbestos Investigators (futureenv.blogspot.com)

Sunday, March 21, 2010

2010 PACNY Environmental Conference

This year probably the biggest impact of the conference was the weather not cooperating with the conference, as the area was hit by a snowstorm during the conference and Long Island was hit with a snowstorm on Friday, the last day of the conference. This hurt the attendance at the conference including one of the speakers presenting and causing several vendors to be missing in action. It was a shame because those of us who attended had a great time and were provided with a lot of information. Vendors attending included: Grayling Industries; DiVal Safety; Aramsco; Fiberlock Technologies; Foster Specialty Construction Brands, and United Rentals to name a few. Dival Safety's booth was showcasing "Green Stuff Absorbent" an environmentally friendly product used to absorb chemical spills. The product can absorb over 325 liquids and chemicals allowing for a broaden HazMat response (visit http://www.divalsafety.com/ for more information).

All the presentations were held in the Tuscarora Room. My favorite presentation was by Mr. Kevin Cannan, President of AAC Contracting Inc, also a former President of PACNY. Mr. Cannan's presentation was a discussion of the industry and a look back and a look forward. I enjoyed it so much I forgot to take notes. Well done Mr. Cannan!

The other presentations included:

- The return of Mr. Craig A. Benedict, Assistant U. S. Attorney, and Mr. Justus J. Derx, Special Agent of the EPA, both discussing recent cases and their current focus in the industry. Both mentioned that their success has led to increased responsibility into new Districts. The major points of their presentation were:

- They view their work in the abatement industry as fighting a spiral down effect. Preventing the degradation of the quality of work in the abatement industry due to contractors/consultants not following the regulations.

- They have now done over 100 individual prosecutions and have not lost one.

- They are now focusing on air sample technicians and project monitors as aiders and abettors of violations of the Clean Air Act rule and making them culpable under standard.

- They are also focusing on the culpability of owners/general contractors on ensuring the legitimacy of the asbestos contractor/consultant.

- Other issues in the industry they discussed include:

- insurance fraud and the use of foreign workforces that are not on your payroll.

- contractors using foreign workforces not on their payroll.

- reminded asbestos companies should have policies on workers moonlighting and using their equipment and inventory.

- Ms. Kimberly Castillon, Assistant Area Director of OSHA, updated the attendees on current remediation industry enforcement actions, she discussed:

- Enforcement has become OSHA's number one priority.

- OSHA expects to perform 750-800 more inspections per year utilizing 130 new compliance safety and health officers. that have been hired nationwide.

- New/revised regulations that are in the pike include Hazard Communication, Silica, Cranes and Derricks, confined space entry for construction and combustible dust.

- The OSHA Region 2 statistics include 5,600 inspections in 2009. 26% of those inspections were in compliance. 13,000 violations were issued averaging 3 violations/inspection. 81% of violations issued were serious violations. The average penalty per serious violation was $1,024.

- Typical remediation industry violations - respiratory protection, recordkeeping, hazardous waste and emergency response, and asbestos.

- Mr. Andrew McClellan, President, Environmental Education Associates, spoke on the impending EPA Lead Renovation, Repair, and Painting Regulation going into effect on April 22, 2010. The major points included:

- Lead abatement is not covered by this rule.

- The rule includes kindergartens and childcare centers.

- If the amount of material impacted is under six (6) square feet interior or twenty (20) square feet exterior, it is considered a minor repair or maintenance and is not covered by the rule.

- Each project requires records be created and filed that must be maintained for three (3) years (recordkeeping requirement).

- Mr. Sean Hickey, Senior Vice President, Rose & Kiernan discussed the Insurance Market. His major points were:

- The insurance market is currently a buyers market.

- Commercial rate changes are averaging -5% with general liability dropping 6% and workmen's compensation dropping 3.7%.

- There is more competition in the Environmental insurance industry. In 2009 there were 15 carriers, now there are 30.

- Mr. Chris Alonge's presentation was exactly the same as the one presented to Metro-AIHA meeting in November (see our entry at http://futureenv.blogspot.com/2009_11_01_archive.html for the specifics). Mr. Alonge presented a revised schedule for the proposed new Industrial Code Rule 56. Submission to GORR by April 2010. Publish proposed revisions in May 2010 in NYS register. Finalized revisions take effect August 2010. Though I suspect that may be overly ambitious. We will see.

Related articles by Zemanta

- PACNY Conference Opens on Thursday, February 25, 2010 (futureenv.blogspot.com)

- Results of the Metro NY AIHA's EHS Global & Local Update Meeting (futureenv.blogspot.com)

- Caution: Stats May Be Slippery (businessweek.com)

Monday, March 16, 2009

2009 PACNY Environmental Conference

On February 26-27, 2009, the Professional Abatement Contractors of New York (PACNY) held their 13th annual Environmental Conference at the Turning Stone Casino and Resort in Verona, New York. If you have attended this conference before you already know that PACNY does a great job of inviting individuals to speak on current contractor/consultant issues and/or current regulatory issues. In what has become a tradition for the conference, the focus of the second day was the New York State Department of Labor (NYS DOL) and what was affectionately referred to as the Chris Alonge Road Show.

Over 200 people attended the conference this year, not a bad number considering the condition of the economy. However, this year the absence of downstate contractors/consultants was particularly noticeable. It was too bad, because this year’s conference was one of the best. The Mohawk Room had nearly 30 vendors including Grayling Industries, DiVal Safety, Aramsco, and Fiberlock Technologies. Aramsco‘s booth was showcasing a new piece of equipment, a floor buffer with an attachment for a HEPA vacuum, that could be used under the NYS DOL Applicable Variance A-3. This floor buffer with the attachment for a HEPA vacuum would allow a contractor using it to perform mastic removal work with a remote decontamination facility.

All the presentations were held in the Oneida Room. One of my favorite presentations was a two part presentation between Mr. Dale Lesinski, Vice President of DiVal Safety and Mr. Eric Giguere. Mr. Eric Giguere was buried alive in a construction accident and told us his story of survival and his life since his near-death experience. Before Mr. Giguere’s presentation, Mr. Lesinki set the audience up with a Behavior Based safety presentation that worked well with Mr. Giguere’s presentation. The presentation created a powerful 1-2 punch for worker safety. This presentation was so powerful we saw several audience members, including myself, wiping tears away.

The other presentations included:

- Dr. Bruce Lippy’s, of The Lippy Group, presentation on lessons learned from Ground Zero and Boca Raton Anthrax Cleanup. Interesting points: (1) Hazwoper procedures should be an integral part of disasters; (2) Better management of critical incident stress among workers; (3) Better management of the transitions from Rescue to Recovery to Cleanup; (4) Most fatalities involved with work zone safety; (5) Better understanding of the linear relationship between extended work schedule and worker risk of injury: (a) 18 hours of sustained wakefulness produces a performance impairment = 0.05% of blood alcohol content; (b) 24 hours of sustained wakefulness produces a performance impairment = 0.10% of blood alcohol content.

- Mr. Aaron Hilger’s, of the Rochester Builders Exchange, presentation on the recent changes to Wick’s Law (Nassau/Suffolk –increase to threshold from $50,000 to $1.5 million) and the economic climate for the construction industry. His discussion also included current view of the stimulus bill and impact of health care reform.

- LeChase Construction/Eastman Kodak’s presentation involved four speakers (Raymond LeChase, Jr., Darren Yehl, Jim Gerek, & Edward Slovak) point of view of the Eastman Kodak’s Footprint Reduction Program. The program consisted of the remediation – demolition of 80 structures totaling over six million square feet.

On the second day the Oneida room presentations included:

- IAQ Technologies’ Mr. Bob Krell did a presentation on Indoor Environments and Green Buildings that was primarily a mold presentation.

- Lawyers from NYS DOL & Mr. Chris Alonge then discussed: (1) The “Asbestos Successor Legislation” that went into effect in July 2008; (2) The Guidance Document version 2.0; (3) Proposed changes for the Emergency Rule Making of Industrial Code Rule 56.

- The final presentation was a panel discussion including Mr. Chris Alonge. This panel discussion was a Q&A session for the panelist to discuss directly with Mr. Alonge. Audience participation was restricted until after the panelist finished their questions.

All in all the conference was very informative and well worth the trip. It was a pleasure to get together with old friends, make some new ones, and reacquaint with some friends we had not seen in years (Special hello to Patty Kirkland of EMSL). Bravo to the PACNY organization and the committee that put this year’s conference together, they did a great job. We look forward to next year’s conference and hope to see you there next year.

Saturday, February 21, 2009

PACNY Conference Opens on Thursday, February 26, 2009

Abatement/Remediation Contractors”. We look forward to going and hope to see some of you there.

Monday, February 02, 2009

NYS DOL Announces Guidance Document

Monday, June 09, 2008

220-H Requirements Posted

Thursday, May 22, 2008

Abatement Lessons Learned From Deutsche Bank Tragedy

On August 18, 2007, a fire at the former Deutsche Bank Headquarters located in Manhattan, New York claimed the lives of two New York City firefighters. After the fire, the Occupational Safety and Health Administration (OSHA) inspected the site and issued citations to Bovis Lend Lease, John Galt Corp., and Paradise Energy Electrical Contractors. These contractors were responsible or involved with the demolition and asbestos abatement work on the buildings. Bovis Lend Lease was being fined $193,000, John Galt Corp. was being fined $271,500, and Paradise Energy Electrical was being fined $6,250. OSHA found the following hazards at the worksite:

- Failing to inspect and maintain firefighting equipment to ensure that the standpipe system was operational and that sufficient water supply and presuure were available for firefighting

- Obstructed emergency exit access (including sealed emergency stairwells, emergency stairwells blocked by construction, and unlighted stairwells)

- Inadequate emergency escape procedures

- Unmarked exits

- Lack of fire extinguishers, emergency alarm procedures, and fire cutoffs

- Failing to develop and follow a fire protection program

- Smoking permitted in work areas

- Temporary structures inside the building made of combustible materials

- Scaffolds erected too close to power lines

- Unprotected sides and edges of work areas, unprotected floor openings, missing or broken guardrails, and missing stair rails

- Exposed live electrical parts, electrical panel boards in wet locations, and other electrical hazards.

Several of these items are reminders for abatement contractors and consultants, building owners, facility managers, general contractors, and project management firms. There are several OSHA regulations that apply to asbestos abatement, other than 1926.1101, and they require:

- That temporary structures, such as the decontamination facility, must be constructed of non-combustible materials such as fire retardant wood.

- Exists must be marked and alternate exits established. For example, using fluorscent paint to mark exits and designate alternate pathways.

- Construct blocked fire exits so workers could still use them. For example installing knives near the exists so workers can cut the poly, and construct kick-out panels to access the fire exits.

- Install a fire extinguisher (rated at least 2A) per 3000 square feet of protected building area. Install sufficient fire extinguishers so that the distance traveled shall not exceed 100 feet. At least one fire extinguisher shall be located adjacent to the stairway.

- Develop and follow a fire protection program that includes: the preferred method for reporting fires and other emergencies; evacuation policy and procedures; emergency escape procedures and route assignments, such as floor plans, workplace maps, and safe or refuge areas; names, titles, departments, and telephone number of individuals both within and outside your company to contact for additional information or explanation of duties or responsibilities under the emergency plan; procedures for employees who remain to perform or shut down critical operations, operate fire extinguishers, or perform other essential services that cannot be shutdown for every emergency alarm before evacuating; and rescue and medical duties for any workers designated to perform them.

New York State Department of Labor mentioned at the PACNY conference that there might be some changes in the future based on the information gathered from this tragedy. From OSHA's press release we can learn some of these lessons now and apply them to our current projects. Should you need any assistance with developing these programs or plans, you can contact us, and we can assist you.

Sunday, May 04, 2008

Operating Engineers Need Asbestos Handler Certificates

OSHA 300A Posting Requirements and 2026 Penalty Updates: What Employers Need to Know

It’s time once again to focus on an important requirement from the Occupational Safety and Health Administration (OSHA) . Employers with 10...

-

The New York City Department of Environmental Protection (NYC DEP) has introduced proposed amendments to Chapter 1 of Title 15 of the Rules...

-

… … … This debate regarding asbestos floor tiles started at the Professional Abatement Contractors of New York's ...

-

Image via Wikipedia The National Institute for Occupational Safety and Health (NIOSH) today invited public comment on a draft document titl...