- supplying personal protective equipment (PPE),

- providing quantitative respirator fit testing,

- providing respirator medical evaluations,

- our monthly Safety Suzy newsletter with content on asbestos, mold, indoor air quality, and occupational safety and health information,

- our blog where we post items of interest and discussion,

- our negative air app,

- our air sampling charts,

- our training library,

- our partnership with SiteDocs,

- and all of it found on FEDTC's website.

Future Environment Designs Training Center specializes in asbestos, indoor air quality, industrial hygiene, and occupational safety training programs. We offer New York State asbestos and mold certification courses. We design, develop, and maintain the various indoor air quality, asbestos, and safety programs that are Keeping Your Employees Safe.

Search This Blog

Friday, October 10, 2025

Future Environment Designs, Inc. Celebrates 37 Years in Business With a New Program Called "After The Refresher"

Tuesday, March 05, 2024

That Time of Year! Conferences, Posting Requirements, and OSHA Violations Increased!

It's that time of year again. We're between conferences. February 15-16, 2024 was the Professional Abatement Contractors of New York (PACNY) Environmental Conference and the Environmental Information Association (EIA) National Conference & Exhibition is March 18 - 21, 2024. This year we have the honor of speaking at both conferences. We are speaking on the "Fallacy of PCM Clearance" in other words 5 reasons PCM should not be used for clearance. We are speaking on Wednesday, March 20, 2024, at 1:00 PST if you happen to be in San Diego, California come down and say hello! We're looking forward to arriving early and seeing the San Diego Wildlife Park and the Zoo, two different areas. Our speech was very well received at the PACNY Environmental Conference. If you would like to see the posts from the PACNY Conference visit PACNY's Linkedin page.

|

| FEDTC's Booth at PACNY Conference |

There are other things also happening at the beginning of the year. For example, remember to post your Occupational Safety and Health Administration (OSHA) 300A if you have 10 or more employees, see last month's post for more information. The 300A, which is the summation of injuries and illnesses your company had in 2023, should be posted from February 1st, 2024 to April 30, 2024. Also, remember certain employers must electronically submit the OSHA 300A information directly to OSHA by March 2, 2024.

|

| 300a Must Be Posted & For Some Must be Submitted |

On January 16, 2024, the OSHA maximum penalties for serious and other-than-serious violations increased from $15,625 per violation to $16,131 per violation. The maximum penalty for willful or repeated violations also increased from $156,259 per violation to $161,323 per violation. These increases happen every January 15th. This year's increase was delayed because January 15th was a Federal holiday (Martin Luther King Day).

Looking Forward to EIA's Conference in San Diego & Visiting the Wildlife Park

Wednesday, August 02, 2023

The 2023 PACNY Fishing Derby - A Beautiful Day on the Lake But Where Are All The Fish?

|

| Sun coming up off Point Breeze |

- Cornerstone - Sunrise II

- Cornerstone - Legacy

- Lozier - Richmond II Salmon Doctor

- United Rentals - Tomahawk

- Paradigm Environmental - Shotgun

- Paradigm Environmental - Gone Costal

- Sessler Environmental Services - Intimidator

- Republic - Double Trouble

- Republic - Troutman

- Future Environment Designs - Catchin’ Hell

- Expert Environmental - Get Hooked

- Abscope Environmental - Make the Turn

- DiVal - Rally Killer

- Aramsco - Mister

- Aramsco- Lake Runner

- AAC Contracting - Bite Me

- First On-site - 3 Dogs

- Metro Environmental - Rusty Lure

- Cornerstone - Bait Master

Monday, October 24, 2022

The Reality of Asbestos Clearance Air Sampling! Are You Sampling Enough?

We attended the Environmental Information Association (EIA) 2022 National Conference and Exhibition in Phoenix, Arizona from March 20, through March 23, 2022. We attended several sessions regarding asbestos where we discussed with some attendees asbestos clearance air sampling and what are the Federal requirements. Based on those discussions we figured it was time to write an article on this topic. To make sure we wrote this article based on general industry practice, versus what we are used to in New York State and New York City, we consulted with Mr. Tom Laubenthal, of TGL Consulting, Inc., and Mr. Dana Brown, of Time's Dark Captains. Since everything else seems to start with the Environmental Protection Agency's (EPA's) Asbestos-Containing Materials in Schools Rule (40 CFR Part 763, Subpart E, known in the industry as the Asbestos Hazard Emergency Response Act (AHERA)) why don't we start there? The AHERA regulation remember applies to schools from Kindergarten to 12th grade (K-12), both public and private schools. The requirements are found in two sections of the rule:

- Response Actions; §763.90 (i)

- Appendix A (to Subpart E) - Interim Transmission Electron Microscopy Analytical Methods - Mandatory and NonMandatory - and Mandatory Section to Determine Completion of Response Actions

For all intents and purposes, these methods serve as the industry standard when final clearance is performed for most asbestos abatement projects, especially when areas are to be re-occupied. We’ll discuss applicability issues as we go.

|

| TEM Analysis |

First, let's discuss the requirement for aggressive clearance sampling. In the AHERA regulation, aggressive sampling means floors, ceilings, and walls shall be swept with the exhaust of a minimum one (1) horsepower leaf blower. Some states and specifications may also require the use of fans as described in the non-mandatory section of Appendix A. The non-mandatory section states, that stationary fans shall be placed in locations that will not interfere with the air monitoring equipment. Fan air is directed toward the ceiling. One fan shall be used for every 10,000 cubic feet (CF) of a worksite. This is required in the New York State Department of Labor's Asbestos Regulation Industrial Code Rule 56 (NYSDOL ICR56) and the New York City Department of Environmental Protection Asbestos Regulation Title 15 (NYCDEP Title 15). However, NYSDOL ICR56 also requires one fan per room in addition to the one fan per 10,000 CF.

|

| This is not in the spirit of the AHERA/NYSDOL ICR56/NYCDEP Title 15 requirements for aggressive clearance sampling. Thank you Greg Mance for the photo. |

As defined by the AHERA rules, final clearance air sampling can be done by phase contrast microscopy (PCM) methodology for projects less than or equal to 160 square feet (SF) or 260 linear feet (LF) by the National Institute for Occupational Safety and Health (NIOSH) 7400 methodology (Issue 3: 14 June 2019 is the current issue). For projects greater than 160 SF or 260 LF clearance shall be done by the AHERA transmission electron microscopy (TEM) method (requirements at 763.90 (i) (4) and Appendix A).

|

| Graphic courtesy Tom Laubenthal |

There are some similarities between the AHERA TEM and NIOSH 7400 methods. For example, the AHERA TEM method (Appendix A) allows for the use of either a 25-millimeter (mm) filter cassette or a 37-mm filter cassette. We haven't used a 37-mm cassette since the industry switched from the old asbestos sampling method NIOSH P&CAM 239 to the NIOSH 7400 method that was formally adopted into AHERA. For sampling, whether it is the AHERA TEM method or the NIOSH 7400 method, we use a 25-mm 3-piece cassette with 50-mm electrically conductive extension cowl cassettes. The two methods require the filter cassette to face 45 degrees downward from the horizontal. The filter material used is mixed cellulose ester (MCE). AHERA TEM method does allow for the use of polycarbonate (PC) filters as well. The PC filters fell out of favor because post-sampling handling was more problematic than the MCE filters. With PC filters, if samples sent to the lab are not handled carefully, the sampled fibers can move significantly from the filter surface. This was widely discussed in the industry in the 1980s. Since then, only MCE filters are used outside of specialty applications.

|

| The filter cassette is to face 45 degrees downward from the horizontal. |

Both methods require blanks, however, that is where the similarities end. The AHERA TEM method requires three blanks two field blanks and one laboratory (sealed) blank. While the NIOSH 7400 method requires a minimum of two blanks or 10% of samples collected with a maximum of 10 blanks. How the blanks are handled is different as well. The AHERA TEM method laboratory (sealed) blank is not opened and kept sealed, while the field blanks are opened for 30 seconds at the entrance to each abatement area and one at an ambient area. While the NIOSH 7400 method requires the blanks to be opened at the same time as the other cassettes just prior to sampling and stored with the top covers of the cassettes that are running and remain open for the duration of sampling (here is an interesting difference, in some places the cassettes are stored in the box with the lid closed or, the way we were taught, they are placed in a Ziploc bag that is used to deliver the samples to the laboratory).

|

| A typical box of air sampling cassettes |

Another difference is that with the AHERA TEM method we use a 0.45-micron (µm) MCE filter and the NIOSH 7400 method uses a 0.8 µm MCE filter. This refers to the size of the air passages in the filter material. Filter manufacturers will color code or mark the label so that the type of filter within the cassette assembly is known to the user and the laboratory.

|

| TEM filter is 0.45-micron. PCM filter is 0.8-micron. |

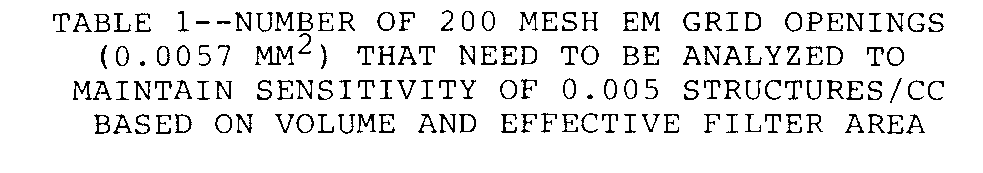

Let's get to some of the interesting items such as how the samples are taken and how many are required. The AHERA TEM method is straightforward, it requires 5 samples inside the work area and 5 samples outside the work area that represent air entering the abatement site plus the blanks (as mentioned above) for a total of 13 samples. These samples should run from 1 to less than 10 liters per minute (LPM) for a total volume of air greater than 1199 liters or greater (see Table 1 below for the recommended sampling volume range for this method, typically the volume range is between 1200 liters and 1800 liters). It is interesting that the maximum flow rate is less than 10 LPM. It would be interesting to find out how many in the industry actually sample at less than 10 LPM (i.e., 9.9 LPM versus 10 LPM). Likely most of the industry merely samples at 10 LPM. The statistical difference between 10 and 9.9 LPM, some regulators insist upon, is statistically insignificant and will affect method performance in no discernable manner. Either way, this means your clearance samples will take a little over 2 hours to collect.

|

|

In speaking with Mr. Tom Laubenthal, we learned at the time this method was developed it became known through the research involved that flow rates higher than 10 LPM could cause fibers to impact the MCE filters vertically and not horizontally to the filter surface. This makes the sample analysis, counting, and identification, difficult and likely biased. This is also the reason the method specifies a second MCE filter under the 0.45 µm sampling filter and the 5 µm diffuser. This additional filter is placed in this manner to attempt to create an even flow across the filter surface so that fibers impact the filter uniformly. Since the fibers are lying flat on the filter this is the reason for turning the sample upright before interrupting the pump flow to ensure the fibers remain on the filter.

|

| Sampling Cassette Configuration |

In the AHERA TEM method, the clearance samples pass when the average concentration of the five samples inside the work area does not exceed 70 structures per square millimeter (s/mm2). See AHERA at 763.90 (i) (3) for an optional clearance test based on the z-test which compares the outside and inside air samples. This is rarely necessary. But cases have occurred when contamination can exist in the air outside the work area that could cause a failure in the work area.

|

| This TEM asbestos image is from the Centers for Disease Control (CDC) "Asbestos Fibers and Other Elongate Mineral Particles: State of the Science and Roadmap for Research" |

The NIOSH 7400 method for final clearance is also interesting when it comes to how the sample is taken and how many are based on the project. For schools, when PCM is allowed, it's 5 samples inside the work area. What's interesting is that the clearance is based on each sample and each sample must be less than or equal to a limit of quantitation (LOQ) for PCM of 0.01 fibers per cubic centimeter (f/cc). Well according to the NIOSH 7400 method how do you achieve clearance at that LOQ? This concept of LOQ is not a concept understood by many that use the NIOSH 7400 method for all its purposes. In the NIOSH 7400 method, this issue is addressed as follows in the section "Sampling", number 4 on page 4. It utilizes the formula below to determine the amount of time needed to achieve the fiber density, E, for optimum filter loading. So, the minimum density the method allows is 100 fibers per square millimeter (mm2). The Ac is the collection area for a 25-mm cassette which is 385 mm2. The Q is the sampling flow rate in LPM, so let's say that is 16 (the maximum flow rate allowed by the method). The L is the concentration of fibers in the air, we are looking to achieve clearance at 0.01 fibers/cubic centimeters (f/cc). So if you plug these numbers into the formula you get a time of 240.6 minutes, which means the sample would have to run for a little over 4 hours at 16 liters per minute (total volume of air of 3,850 liters).

Realize that is running the sample at 16 LPM. If your pump/flowmeter can only go to 15 LPM then you would have to run the sample for 256.7 minutes which is just short of 4 hours and 15 minutes. The lower the flow rate, the longer time it will take to meet sample volume requirements.

|

| Airbox High-Performance Air Sampler |

Many believe or have been misled to believe that PCM sampling is the same as TEM sampling in terms of sampling volume. This is not the case. A PCM sample volume meeting AHERA clearance requirements are not at 1200 liters. To do so is outside of the NIOSH 7400 method requirements for this purpose. In the NIOSH 7400 method, the issue regarding "relatively clean" environments" is addressed on page 4, number 4, note number 1 which states "In relatively clean atmospheres, where targeted fiber concentrations are much less than 0.1 f/cc, use larger sample volumes (3000 to 10,000 liters) to achieve quantifiable loadings." Even though the formula calculates that 3,850 liters of air should be collected, many people use note 1 to collect 3,000 liters of air for clearance. Either way clearance samples should be collected using no less than 3,000 liters of air as the minimum allowed for the NIOSH 7400 method requirements and AHERA compliance.

|

| PCM image of fibers |

The true problem is the NIOSH 7400 was never designed as a clearance tool, it was designed as a personal air sampling method. NIOSH and the Occupational Health and Safety Administration (OSHA) still view the method in that manner officially. The other problem with PCM is that all fibers meeting method criteria are counted, not just asbestos fibers. The AHERA TEM method is the only procedure that was designed as a final clearance air sampling method. Only asbestos fibers/structures are counted in the analysis meeting method criteria for size, and those much smaller than can be determined by the PCM.

|

| EPA's Silver Book |

Realize this is not something out of the ordinary the EPA's publication "Measuring Airborne Asbestos Following An Abatement Action" (otherwise known as the Silver Book) written in November 1985 on page 2-6 recommends the sample volume for the PCM analysis should be a minimum of 3,000 liters of air (though at the time of this publication it was describing the NIOSH P&CAM 239 PCM methodology). In addition, in March 2015 the EIA published a revision to the EPA's 1985 document "Guidance for Controlling Asbestos-Containing Materials in Buildings"(EPA 560/5-85-024, known as the Purple Book). This nationally peer-reviewed document was re-titled "Managing Asbestos in Buildings: A Guide for Owners and Managers." Chapter 5 (on page 88) says the minimum sampling volume of 3,000 liters of air for samples taken to meet the NIOSH 7400 method requirements for LOQ sampling. Mr. Dana Brown did a video regarding the LOQ issue and why NIOSH 7400 method is not the best choice for clearance, you can see it below.

This doesn't count that we have called for the AHERA TEM method to be utilized for asbestos-containing floor tiles and mastic removals based on our previous blog post "Asbestos Floor Tile Debate", published in the August 2017 issue of Healthy Indoors Magazine, which found that the NIOSH 7400 method is not able to analyze the type of fibers (Grade 7-Shorts and Floats that are known to be less than 5 microns) found in these materials because of the known small fiber sizes generated by floor tile work. Whether AHERA-based work or asbestos abatement where re-occupancy will occur, the surest way to make sure an area is ready to be given back to the public to be free of asbestos as practicable by current methods, and the fastest method for clearance would be the AHERA TEM method.

|

| NYSDOL ICR56 Definition of an Asbestos Project |

Of course, those of you who work in New York State or New York City realize these requirements only apply to public and private K-12 schools. So they don't apply to other buildings, or do they? First, let's take the NYSDOL ICR56 Subpart 56-4, page 35 is the air sampling requirements. 56-4.6 "Test Methods" on page 36 says "the same NIOSH approved methodology for project air sampling and for analysis of the air samples shall be used at all phases of an asbestos project that require area air sampling and analysis, with the possible exception of clearance air sampling." This means that the NIOSH 7400 method must be followed for all phases except clearance (Phase IIC of the asbestos project) this allows you to use either the NIOSH 7400 method or the AHERA TEM method instead for clearance. So this means you have to follow the NIOSH 7400 method's LOQ requirements for all phases (Phase I B and Phase II A, B, & C) of the asbestos project. In addition, the NYSDOL ICR56 regulation for clearance is less than 0.01 f/cc so that changes the formula again. Let's use 0.009 f/cc for the L instead and still use 16 liters per minute, well that means the sample has to run for 267 minutes, almost 4 hours, and 30 minutes (a total volume of air of 4,278 liters).

|

The consummate leader cultivates the moral law, and strictly adheres to method and discipline; thus it is in his power to control success. ~ Sun Tzu |

So why does everyone sample 1,200 liters of air for all samples? On April 8, 2011, the New York State Department of Health (NYSDOH) Wadsworth Center issued frequently asked questions (FAQs) regarding asbestos/fibers analysis that were developed through the collaboration of the NYSDOH Environmental Laboratory Approval Program (ELAP) and the Bureau of Occupational Health and the NYSDOL. In this FAQ is FAQ#13: What is the minimum sampling volume to be collected for air sampling associated with (a) post-abatement (clearance) air monitoring and (b) post-abatement area monitoring for PCM analysis? The answer that was given was: Within the upcoming revision to NYS Industrial Code Rule 56, minimum air sample volume requirements

|

| Buy our Asbestos Air Sampling Chart here. Read about our Asbestos Air Sampling Charts here. |

Sunday, May 15, 2022

New York City's Asbestos Regulation Revised. Again!

On April 28th, 2022, New York City published a notice of adoption in the City Record for the revisions to the Asbestos Control Program Rules and Regulations (RCNY Title 15 Chapter 1). These revisions will become effective on May 28th, 2022. Of course, there are some significant changes that asbestos contractors, asbestos consultants, & asbestos investigators should be prepared for. These changes include:

|

| NYCDEP will need to revise the confined space standard reference to 1926 Subpart AA Confined Spaces in Construction |

- New wording regarding making a false statement/documents not only to the New York City Department of Environmental Protection (NYCDEP), but to any city agency or any individual related to an asbestos project, asbestos surveys, or any document required to be filed under these rules.

- The addition and subtraction of some definitions:

- Airtight was added which "means secured and sealed utilizing 6 mil plastic sheeting and tape to make a barrier through which no air, dust or debris can be transmitted." Not sure we like this definition. No air can be transmitted, with just plastic and tape?

- ARTS E-File was added. Which is the web-based filing system that NYCDEP uses to file all things related to asbestos projects.

- Asbestos Project Air-Sampling Technician, Confined Space, Occupational Safety and Health Administration (OSHA) Construction Safety and Health card, and warning line system were added.

- Bound Notebook was subtracted, but a Permanently bound log was added. "Permanently bound log shall mean a log consisting of sequentially numbered sheets of paper, pre-printed or handwritten, that is permanently secured to the front and back covers by stitching, glue, and binding that creates a strong and lasting bond and makes readily discernible the removal or insertion of sheets after the log’s first use." We added the bold section to point out that a composition notebook no longer can be used. Since they are not glued. We did a quick search and found that "Smyth Sewn (also known as Section Sewn)" would meet this requirement, we're sure there are others.

- The definition for disturb has been modified and "shall mean any activity that disrupts, impregnates, or strips the matrix of asbestos-containing material (ACM) or presumed asbestos-containing material (PACM), or that generates debris, visible emissions, or airborne asbestos fibers from ACM or PACM. This includes but is not limited to the removal, encapsulation, enclosure, renovation, repair, or cleanup of ACM or PACM." Of course, when we read this we had to whip out our Thesaurus (dusting it off or of course, we could have googled it, sorry we're a little old school) to see why NYCDEP uses the word impregnate (obviously it would not be our first impression of the word, which leads to many very bad images)! The second definition for impregnate is to soak or saturate (something) with a substance. Interesting wonder if there might have been a better word to use?

- The definition of the log was changed to "shall mean a permanently bound official record of all activities that occurred during the project. One log must be maintained by the abatement contractor in accordance with section 1-92 Work Place Entry and Exit Procedures, and one log must be maintained by the air monitoring company in accordance with section 1-37 Sampling Equipment Requirements."

- They added "Project monitor’s report. “Project monitor’s report” shall mean the "Form ACP-15" that the project monitor is required to submit for partial or complete asbestos project closeout as approved by NYCDEP."

- Variances must be made through the ARTS E-File System. Submitted by a project designer and authorized by the building owner or authorized agent. Including the description of the deviation, and a description of the hardship preventing the required procedures from being employed. A sketch is no longer allowed it must be a drawing.

- The addition of "any abatement activity to be performed within a work area located in a confined space" to the requirements of when an asbestos abatement permit is required. This requires a Work Place Safety Plan (WPSP). They added that the asbestos abatement permit would expire upon the expiration date of the asbestos project notification ACP-7 form. In addition, sections in "Failure to terminate asbestos abatement permit within year" were deleted related to extending the permit. Regarding the letter from the registered design professional finding additional ACM on a project, it must be filed through the ARTS E-File.

- Emergency project notifications must be filed through the ARTS E-File system (instead of telephone communication), If the applicant does not have a valid ARTS E-File account, then telephone notification shall be made to 311. The cover letter that accompanies the ACP-7 Form must be from the building owner or their authorized agent and must include:

- the nature of the emergency;

- a description of the scope of work. With respect to projects commenced under this section, the department, based on an inspection by the department and other relevant agencies, may exempt the project from the requirements of 15 RCNY § 1-26 Asbestos Abatement Permits.

- The Certified Asbestos Investigators (CAI) must respond to the NYCDEP’s request for inspection within fourteen (14) business days and provide a date, time, and location for an inspection which is within 21 days of the date of the request. Failure of the investigator to either respond to the NYCDEP’s request for an appointment or provide a date, time, and address for an inspection will result in the suspension of the CAI's certificate until such appointment is completed and these records are made available for inspection.

- Chain of custody forms (regarding the air sampling) are now part of the project record and shall be kept on-site at all times. The chain of custody forms, along with the project air sampling log, and a copy of the project monitor's report is added to the records the asbestos abatement contractor shall maintain for at least 30 years after the end of the project.

- Changes to air sampling requirements include cassettes that "must be labeled with sample identification numbers prior to the commencement of air sampling". Air sampling assembly must be checked for leaks and occlusions "throughout the shift and documented in the project air sampling log." The project air sampling log must be a "permanently bound book." Added to the notes of the air sampling table "Transmission Electron Microscopy (TEM) is required in schools in accordance with the Environmental Protection Agency's (EPA) Asbestos Hazard Emergency Response Act (AHERA) regulations." and removed from the notes was "or the pre-abatement area sampling result(s) for interior projects where applicable." In addition, the following statement was added wherever multiple samples are required "which must be representative of the work area. The air samplers must be placed separate and apart from one another and must not be grouped together." For clearance sampling "samplers shall be no further than (vs approximately) 50 feet from the entrance to the work area."

- During abatement air sampling for minor projects was added: "For minor projects employing glovebag or tent procedures, one area sample shall be taken outside the glovebag or tent, not more than five feet from the uncontaminated entrance to the glovebag or tent." According to NYCDEP, this was added to be consistent with NY State (NYS) requirements regarding air sampling for minor projects. Well, NYS Department of Labor Industrial Code Rule 56 (NYSDOL ICR56) does not require air sampling during abatement for minor projects. It does require clearance upon glovebag failure or loss of integrity or tent failure or loss of integrity or incidental disturbance projects, but not during abatement. In fact, this change would require clearance of the minor project if the during abatement sampling result exceeded 0.01 fibers per cubic centimeter (f/cc), or if there were visible emissions detected during the project, or if the work area to be reoccupied is an interior space at a school, healthcare, or daycare facility.

- They modified the section Materials and Equipment, with "Ladders or scaffolds of sufficient dimension and quantity shall be available so that all work surfaces can be easily and safely reached by inspectors and asbestos handlers." Asbestos handlers were added to the section. In addition, these subsections were added:

- Ladders: Where ladders are used to access or reach work surfaces for the conduct of abatement activities, care must be taken to prevent breaching of the containment areas and the ladder’s integrity must be maintained to ensure safety. Ladders and their use shall comply with OSHA 29 CFR 1926. Subpart X Ladders 1926.1053.

- Scaffolds: Where scaffolds are used to reach work surfaces or for the conduct of abatement activities, scaffold joints and ends shall be sealed with tape to prevent the incursion of asbestos fibers. Scaffolds and their use shall comply with OSHA 29 CFR1926. Subpart L Scaffolds 1926.450; 451 and 452.

- Walking Surfaces. Walking and working surfaces shall be protected from tripping or stepping into or through holes or openings, including skylights, by covers secured to the surface in accordance with OSHA Section 29 CFR 1926.501. According to NYCDEP, they added this section due to a recent fatal accident at an asbestos work site. We did a search and it seems this accident may have happened on November 1, 2021. It was reported by the NYC Department of Buildings (NYCDOB) as the Gowanus Roof Fall. Workers were performing asbestos abatement work on the roof of a three-story building at 289 3rd Avenue, Brooklyn. One of the workers left the work area to use the restroom and apparently fell through a 15-inch gap between the building and the supported scaffold, falling approximately 25 feet from the roof onto a first story set back in the rear of the building. The worker died of his injuries. OSHA did an inspection of this accident and issued 3 scaffold violations and 2 ladder violations for a total of $40,604 in fines, which are being contested.

- The abatement contractor's log requirements were moved to section 1-92 Work Place Entry and Exit Procedures. "The abatement contractor’s log shall be permanently bound and at a minimum shall identify fully the building owner, agents, contractor(s), the project, each work area and worker respiratory protection employed, and other pertinent information including daily activities, cleanings and waste transfers, names and certificate numbers of asbestos handler supervisors and asbestos handlers; results of inspections of decontamination systems, barriers, and negative pressure ventilation equipment; summary of corrective actions and repairs; work stoppages with reason for stoppage; manometer readings at least twice per work shift; daily checks of emergency and fire exits and any unusual events."

- Personal protective equipment shall be provided by the abatement contractor.

- NYCDEP added the following to the workplace entry and exit procedures: "When abatement activities are located in a confined space the contractor must comply with all the requirements set forth in OSHA 29 CFR 1910.146.and 1926.21(a) and (b)." This is very interesting because OSHA regulations 1910.146 do not apply to the construction industry. Its 1926 Subpart AA Confined Spaces in Construction applies to the construction industry. Read our blog post regarding the Confined Spaces in Construction standard and its requirements (very similar to the General Industry standard 1910.146, but with specific differences related to construction and technology that is available today that was not available when the 1910.146 came out).

- An interesting change is that chutes can only be used inside a work area that is under negative pressure. Deeming that chutes to transport asbestos from rooftops is unsafe. We wonder what evidence they have for this?

- Encapsulation and Enclosure procedures must be conducted with the full containment of the work area or the tent procedures. Some other modifications.

- Glovebag procedures now require "A visual clearance inspection must be conducted by the asbestos handler supervisor and project monitor after the work area dries, to ensure the absence of ACM residue or debris in the work area. The clearance inspection must be documented in the abatement contractor’s log and the project air sampling log."

- Added air monitoring in accordance with the air monitoring sections 15 RCNY §§ 1-31 through § 1-45 was added to the Tent procedures section, along with "A visual clearance inspection must be conducted by the asbestos handler supervisor and project monitor after the work area dries, to ensure the absence of ACM residue or debris in the work area. The clearance inspection must be documented in the abatement contractor’s log and the project air sampling log."

- Foam Procedure for Roof Removal changes include the establishment and maintenance of a warning line system on the roof throughout the project, the contractor must comply with OSHA 1926 Subpart M, specifically 1926.501 Duty to have fall protection & 1926.502 Fall protection systems criteria and practices, exterior or interior chutes are prohibited to transport asbestos-containing roofing material (ACRM) from the roof to lower floors, and visual inspection must be documented in the abatement contractor's log and project air sampling log.

- Foam/Viscous Liquid Use in Flooring Removal changes includes visual inspection must be documented in the abatement contractor's log and project air sampling log.

- Abatement from Vertical Exterior Surfaces changes include the contractor must comply with OSHA 1926 Subpart M, Fall Protection, 1926 Subpart L, Scaffolds, and the NYC Building code, change to sidewalk bridges is "Sidewalk bridges in the restricted area shall be covered with two layers of fire retardant 6-mil plastic, placed over and secured to the bridge, spread across the full width of the bridge and up the interior walls of the bridge so the walls are fully plasticized" and the clearance inspection must be documented in the abatement contractor's log

- Controlled Demolition with Asbestos in Place has been changed "A condemnation order or declaration issued by the NYCDOB or a signed and sealed condemnation letter from the Owner’s registered design professional which has been acknowledged by the NYCDOB must be submitted to the NYCDEP through the ARTS E-File system. A site-specific scope of work identifying the steps to control asbestos emissions during the controlled demolition must be submitted and approved by NYCDEP prior to the commencement of work.

- The final cleaning procedures were changed to add "After the plastic barriers on the walls and floors have been removed, a third cleaning shall be performed of all surfaces in the work area by wet cleaning and/or HEPA vacuuming. A minimum of a one-hour waiting period shall be conducted to allow the work area to dry prior to the visual inspection by the air monitor and asbestos supervisor."

Wednesday, February 16, 2022

PACNY's Environmental Conference Is Back!! Counting Down The Days to March 3 and March 4, 2022!!!

The Professional Abatement Contractors of New York (PACNY) have announced the dates for their annual Environmental Conference to be held on March 3rd and 4th, 2022. It will be held at the Turning Stone Resort & Casino in Verona, New York. Visit Turning Stone Casino's website for pandemic questions. To register for the conference or sponsor the conference click here!

|

| Return of New York State Department of Labor Panel |

|

| Happy Hour At the Exhibition Hall |

Saturday, July 17, 2021

Future Environment Designs wins the 8th Annual Pro/Am PACNY Fishing Tournament

On the morning of July 7, 2021, Future Environment Designs participated in the 8th Annual Professional Abatement Contractors of New York (PACNY) Fishing Pro-Am Tournament. The tournament was based out of the Lake Breeze Marina, Kent, New York, and on Lake Ontario. It was an iffy day with a thunderstorm passing through just before the tournament started and the lake was a bit rough with 2-4 foot waves. There were 17 boats in this year's tournament (a nice turnout considering the recent easing of Covid restrictions). They were:

- AAC Contracting - Free Spirit

- Cornerstone Training Institute (CTI) - Sunrise II

- CTI - Legacy

- CTI - Trolling Tails

- Lozier - Screaming Reels

- US Ecology - Reflection

- US Ecology - Shotgun

- Metro - Rusty Lure

- Dival - Reel Excitement

- Abscope - Troutman

- Sienna - Get Hooked

- ECG - Richmond 4

- Future Environment Designs - Catchin Hell

- Sessler - Intimidator

- Aramsco - Mister

- First On-Site Restoration - 3 Dogs

- HSE - Bite Me

|

| Future Environment Designs and the Catch 'N' Hell Team |

Update of Dust and Debris Sampling in New York State: What Asbestos Inspectors Need to Know

On July 16, 2016, we blogged about " Asbestos Dust Sampling in New York State ," since that post had over 1,550 views and will be ...

-

The New York City Department of Environmental Protection (NYC DEP) has introduced proposed amendments to Chapter 1 of Title 15 of the Rules...

-

… … … This debate regarding asbestos floor tiles started at the Professional Abatement Contractors of New York's ...

-

Image via Wikipedia The National Institute for Occupational Safety and Health (NIOSH) today invited public comment on a draft document titl...