Future Environment Designs, Inc. (FEDTC) was a proud Sapphire Sponsor at the 27th Annual Environmental Conference hosted by the Professional Abatement Contractors of New York (PACNY). Held at the illustrious Turning Stone Casino in Verona, New York, on February 15th and 16th, 2024, this two-day event was packed with enlightening presentations, industry updates, and valuable networking opportunities.

|

| FEDTC's Booth at PACNY's Environmental Conference |

Day One Highlights: A Deep Dive into Environmental Challenges

The conference kicked off with an array of expert speakers, setting the tone for an engaging and informative event. Ben Reich of Eurofins opened the sessions with his talk on "Interpretation of Laboratory Results: Complicated Considerations Challenging Mold Sample Reporting." Reich's detailed analysis shed light on the complexities of mold sample reporting, emphasizing the need for meticulous interpretation of laboratory results.

|

| Ben Reich of Eurofins |

|

| Charles Merritt of Merritt Environmental Consulting Corp. |

Brent Kynoch of the Environmental Information Association (EIA) followed on the first track with "Compliance Chronicles: Understanding Environmental Protection Agency (EPA) Lead Rules." His presentation provided a thorough overview of the current EPA lead regulations, helping attendees navigate the intricate compliance landscape.

|

| Brent Kynoch of EIA |

Lisa Rogers of Mycometer and Frank Ehrenfeld of Eurofins collaborated on "American Society of Testing Materials (ASTM) Standards: Reducing Risk and Adding Value for the Analytical, Environmental, and Occupational Health & Safety Professional." Their presentation highlighted the importance of ASTM standards in mitigating risks and enhancing value across various sectors, including analytical, environmental, and occupational health and safety.

|

| Frank Ehrenfeld of Eurofins, and Lisa Rogers of Mycometer |

Jerrod Garrett from LeChase brought a practical perspective with "Safety by Design: The Crucial Role of Well-Considered Task Hazard Analysis." Garrett's insights into task hazard analysis underscored the importance of proactive safety measures in project planning and execution.

|

| Jerrod Garrett from LeChase |

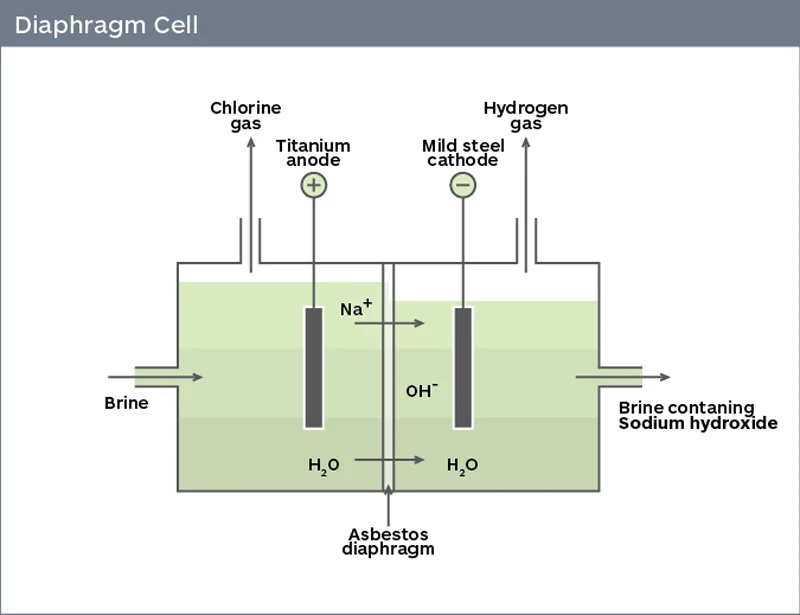

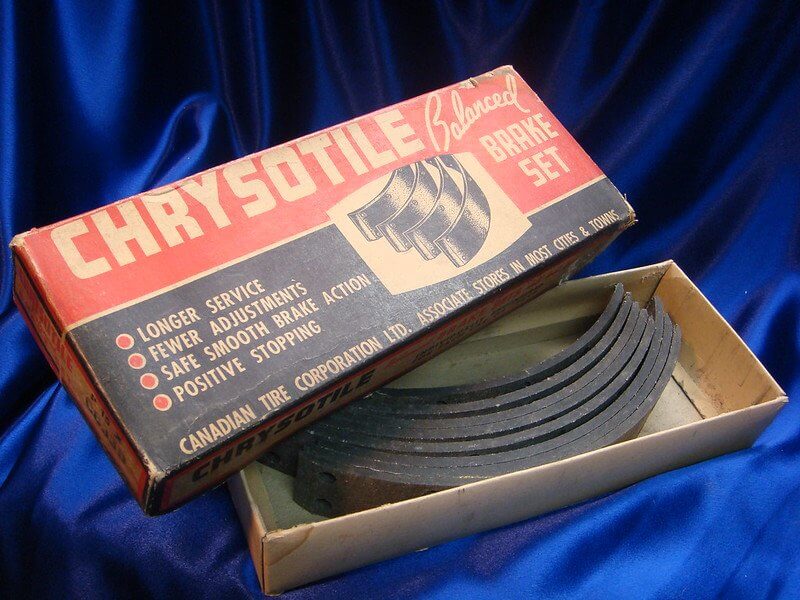

The Fallacy of PCM Clearance: A Critical Examination

Just before lunch, we had the honor of presenting on a topic close to our heart: "The Fallacy of PCM Clearance." Our presentation aimed to challenge the conventional reliance on Phase Contrast Microscopy (PCM) for clearance in asbestos abatement projects. By highlighting PCM's limitations and potential inaccuracies, we advocated for more rigorous and reliable clearance methodologies, like the EPA's Asbestos Hazard Emergency Response Act (AHERA) Transmission Electron Microscopy (TEM) method.

|

| Angelo Garcia, III of Future Environment Designs, Inc. |

Addressing Disposal Challenges and Standards Updates

Also just before lunch, Jonathan Wagman, the Area Director of Industrial Sales for NY/NE Market for Waste Management, tackled a critical issue with "PCB Disposal: Identification and Disposal of PCB Contaminated Debris." Wagman's expertise in hazardous waste management offered valuable guidance on identifying and properly disposing of PCB-contaminated materials.

|

| Jonathan Wagman of Waste Management |

Cole Stanton, representing Sentinel Products, updated attendees on the latest "Institute of Inspection Cleaning and Restoration Certification (IICRC) standards" with his presentation. Stanton's discussion on standards in the restoration industry highlighted recent advancements and best practices, ensuring professionals stay abreast of current protocols.

|

| Cole Stanton representing Sentinel Products |

Engaging Panel Discussions and Safety Insights

|

| Lunch and Networking Break |

After lunch, the conference continued with the two tracks coming together for the PACNY Panel Discussion featuring insights from industry leaders including Jesse Scuderi of AEG, Angela Liddell of Paradigm, and Mike Waller of Lozier. Kevin Hutton of EAST, acted as the moderator. Their dialogue on "Project Designers Discuss Variances and Project Design" offered diverse perspectives on tackling variances and optimizing project designs.

|

| Jesse Scuderi of AEG, Mike Waller of Lozier, and Angela Liddell of Paradigm |

After the Variances panel discussion, we returned to the two-track presentations. The first track was the collaboration between Jeremy Starr of MSA and Jerrod Garrett of LeChase in "Elevating Safety: Unraveling the Importance of Fall Protection for Contractors and Consultants" which was particularly impactful. Their emphasis on fall protection underscored the critical need for comprehensive safety protocols in the construction and environmental sectors.

|

| Jeremy Starr of MSA |

Joel Hoomans from Livingston Associates discussing "Attracting and Retaining the Best Talent and Managing an Intergenerational Workforce" was in the second track. Hoomans' strategies for workforce management resonated with many attendees facing challenges in talent retention and engagement.

|

| Joel Hoomans of Livingston Associates |

Finishing Day One and Heading Into Happy Hour

Elizabeth Kirkland of the New York State Department of Labor wrapped up the day's sessions with "Common DOL Inspector Observations." Kirkland's firsthand insights into frequent violations and inspection observations provided invaluable knowledge for ensuring compliance and avoiding penalties.

|

| Elizabeth Kirkland of NYSDOL |

At the Happy Hour, after day one of the conference, attendees further discussed and got better acquainted with the speakers, made new connections, met the conference sponsors, and left day one with a renewed commitment to advancing environmental practices. Stay tuned for our detailed coverage of the presentations and insights from the second day of PACNY's 27th Annual Environmental Conference!